Difference between revisions of "NVGate Torsional"

| Line 195: | Line 195: | ||

|- | |- | ||

|bgcolor = "#FBBCB7"|Twist measurement based '''on integration of the angular speed''' (torsional)''' is not stable''' | |bgcolor = "#FBBCB7"|Twist measurement based '''on integration of the angular speed''' (torsional)''' is not stable''' | ||

|bgcolor = "#5EF86D"|'''Twist signal is stable and do not diverge'''. Indeed the OROS Twist algorithm | |bgcolor = "#5EF86D"|'''Twist signal is stable and do not diverge'''. Indeed the OROS Twist algorithm does not use integration techniques | ||

|} | |} | ||

Revision as of 16:59, 1 June 2020

OROS propose a comprehensive suite for torsional measurements and analyses. It addresses most of the torsional, cyclic and rotational resonances issues. For both R&D and diagnostics, the latest OROS analyzer feature solutions for transmissions, engines and electric machinery vibration analysis.

On reciprocating machinery (diesel engine, pump) or any acyclic rotating devices (generator,compressor), the cause of torsional vibrations often comes from the non-homogeneity of the angular speed. The analysis of the instantaneous angular speed inside each shaft revolution provides the essential information. Such analysis is helpful for vibrations reduction during prototyping or even for source identification while doing service diagnostics.

The common way to measure instantaneous velocity is to install a coding wheel or a rotary encoder on the shaft. The rate of pulse delivered by such device is directly proportional to the RPM speed during the last pulse interval. On most vibration analysers, this type of measurement needs a specific conditioner(usually optional external boxes) which transforms the pulses train into a DC voltage proportional to the RPM. These conditioner devices are expensive, lead to more cable and are often limited to 2 probes and so on. But the main inconvenience is the phase error they introduce due to their internal response time.

OROS propose an integrated frequency to RPM converter which avoids the above-mentioned inconveniences.

Frequency to RPM converter (Torsional inputs)

This option transforms each external Synch input into a frequency to RPM converter (called IVC, allows handling up to 6 torsional/acyclic inputs at a time). This integrated converter benefits of the high accuracy of the 3-Series analysers Ext. synch inputs (over sampled up to 6.4 MHz). As a matter of fact the sampling of such pulse rate must be very accurate in order to avoid speed jitter on the result.

Specifications

The IVC (Instantaneous angular Velocity Converter) option features the following main specifications:

· Number of pulses/rev: 1 to 4096

· Max pulse frequency: 40 kHz 64 times oversampled,

· Max angular speed:

Max RPM = (40 000*64)/pulse per revolution example : 12 800 RPM with 200 Pls/rev

· Missing teeth management: up to 3 consecutive teeth.

· Available filters: HighPass, LowPass; BandPass, StopBand, Integrator (single or double) and differentiator

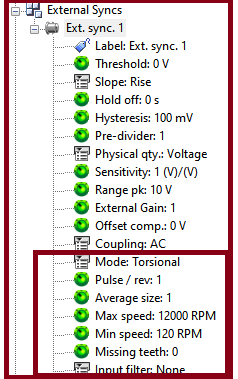

Ext synch Input. Settings

On the front end, the ext. synch input can be used as a:

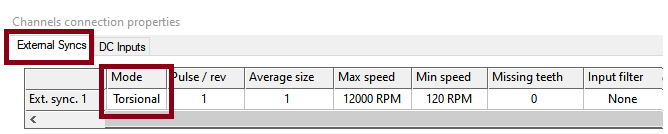

- Mode: This setting allows selecting available signal generated by the Ext. synch input to be used by the NVGate analysis components.

| Mode | Description |

| Trigger | The Input generates events only. It can be used as trigger, start and stop of plug-in analyzers and be recorded. Recorded event occurs as 0/1 V signals. Note that the trigger event remains available on any mode. |

| Tach | The input generates a tach signal (RPM and revolution phases) in addition to the events. |

| Torsional | The input generates the instantaneous velocity measured with the F. to V converter from a pulses train. The torsional signal is considered as a dynamic input. It appears as Tors # in the inputs list (# being the Ext sync number) |

| Torsional + Tach | Same as above plus the tach signal is also available. The revolution phase correspond:

|

| Sampling | The detected pulses on the inputs will be used to synchronize the SOA re-sampling algorithm. The number of pulse/rev is f free and may be different from the SAO resolution. |

| Sampling + Tors | Combine the sampling and the Torsional modes. Both angular re-sampling and instantaneous velocity are provided by the input |

| Sampling + Tach | Combine the sampling and the Tachometer modes. Both angular re-sampling and RPM measurement are provided by the input |

| Sampling + tach + tors | Combine the sampling, the Tachometer and the Torsional modes. Angular re-sampling, Tachometer speed and instantaneous velocity are provided by the input |

- Pulse / rev: the number of pulses per revolution. The user can enter an integer value between 1 and 4092. For a non-integer number of pulses per revolution the user must use a virtual tach.

At least the filter which let you integrate or differentiate the RPM speed to get respectively plane angle deviations and angular accelerations for the analyses.

Fractional missing pulses management

The missing pulses are a common situation faced while doing torsional measurement. The missing pulse can come as a feature of the encoder (like the common 60:2 encoders). But most of the measurement done on the industry do not offer the comfort of an encoder or gear teeth access.

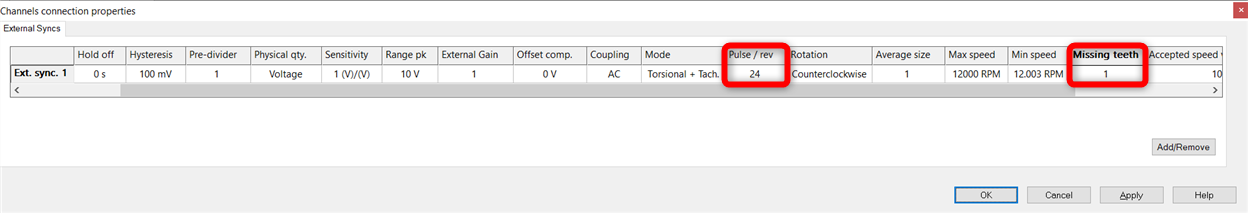

- Missing teeth: This setting indicates the number of possible consecutive missing teeth (meaning no pulses). In such case depending on the active mode:

The system interpolates the missing pulses intervals in order to maintain the instantaneous speed at a continuous level during the missing pulses.

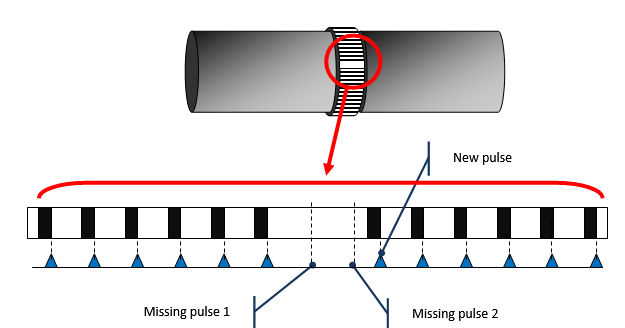

A very useful solution is the piano (or zebra) tape which is glued on the shaft and read by an optical probe: Easy to install and to use.

But the main problem is to have an entire number of pulses. This is never achievable because the various parameters are difficult to control: Black/white period, diameter of the shaft, thickness of the tape/glue. Well, don't try, this is not possible.

The solution is to leave a hole which is interpreted as missing pulse. Due to the above variables it will be a fractional number of missing pulse.

OROS torsional function is able to manage such fractional pulses. It offers to achieve torsional measurement on the field in a simple and easy way.

Piano tape junction for fractional missing pulse management

The empty area (missing teeth) length at the piano tape junction must be included between 1 and 3 teeth. The number of missing teeth must be set to the exact number of missing teeth: In this example: 2.

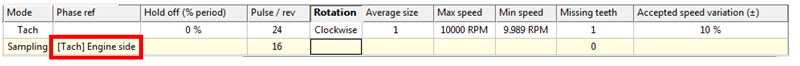

Note: the total number of teeth includes the missing teeth. By example, an encoder with 24 pulse/rev and 1 missing teeth must be set as :

The empty area (missing teeth) length at the piano tape junction must be included between 1 and 3 teeth. The number of missing teeth must be set to the exact number of missing teeth: In this example: 2.

Note: the total number of teeth includes the missing teeth.

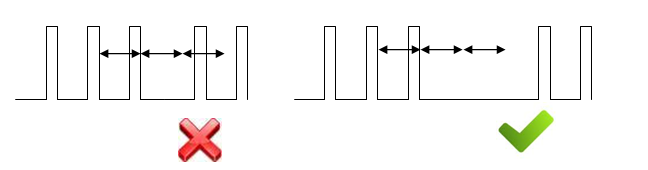

Attention: The time lap of the first missing pulse must be longer than twice the time lap of the previous pulse interval

It is recommended to set the instrumentation in order to limit the number of missing pulse below 3s: Indeed long interval without pulses will lead to a strong order 1 artefact in the instantaneous speed signal due to interpolation of sample. Remaining below 3s for the missing pulse provide correct measurements.

Tutorial

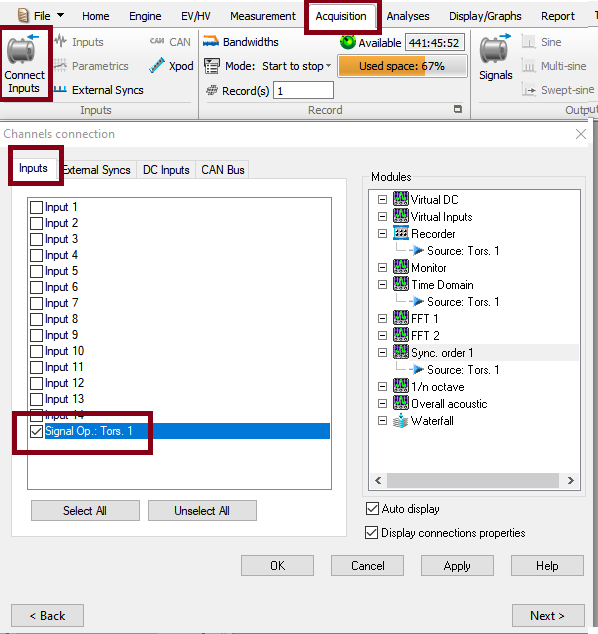

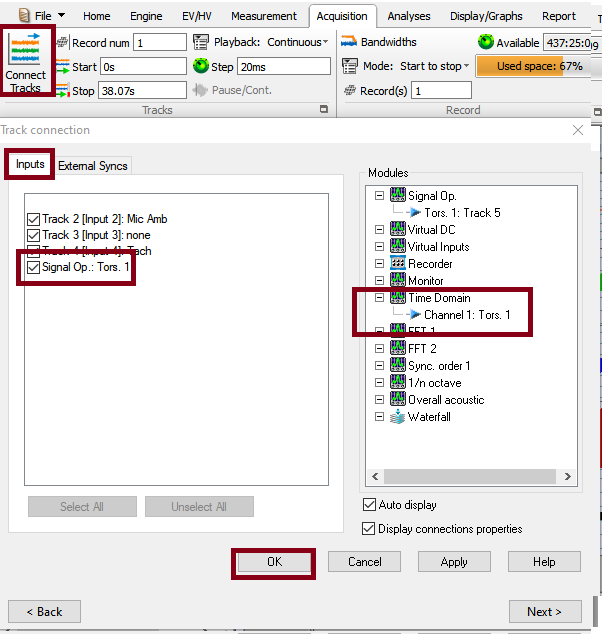

In on-line mode, the torsional inputs appear as additional channels in the channel connection dialog box. They are identified as Tors. x from the Signal Op. resource (not visible in the ASB). These signals can be dispatched exactly as the standard inputs ones :you can connect them to the record, and to any analysis plug-in.

Both instantaneous velocity channel and pulse train can be recorded at the same time.

Online mode

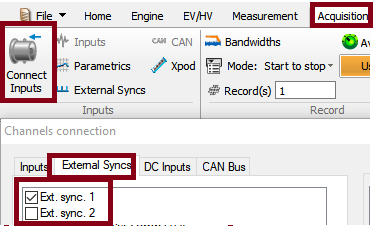

- Plug your tachometer on ext synch channels,

- Activate the Ext-Synch channels and press OK

- Set the ext synch mode as torsional.

- A new input is created : this is the signal of the instantaneous velocity. It can be connected for analysis to any NVGate plug in.

- The non cyclic behaviour of a shaft can be analysed :

- By the order analysis plug-in, providing order profiles

- By the time domain analysis plug-in, for RPM over revolution profiles

- By the FFT analyser plug-in, for displaying the Shaft view to visualize the evolution of speed during one revolution.

- The torsional behaviour of a shaft (crankshaft, alternator) or a driving belt (service belt) can be excited by its acyclic motion. In such a case the phenomena are analysed order by order using the cross-phase tracking capabilities of the SOA Plug-in. In that case 2 or more torsional inputs are used on different locations of the shaft, or on each pulley driven by the belt.

Post-processing

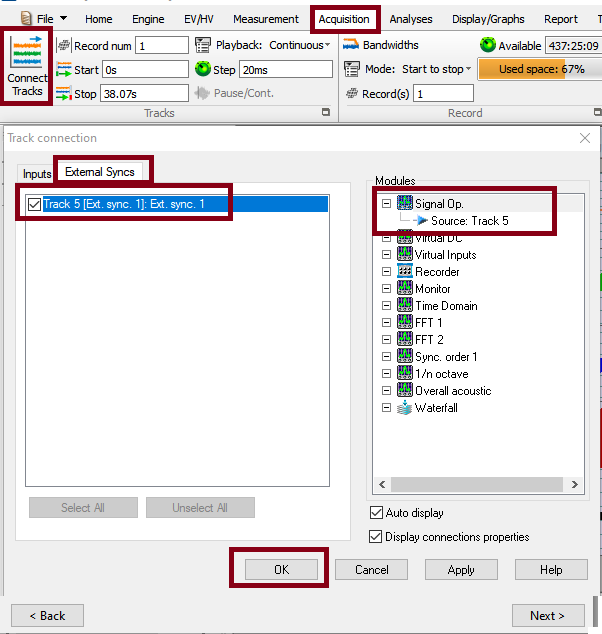

For post-analysis purposes, the way to operate depends on the type of recorded signal:

- If the converted signal (Tors x) have been recorded, the post analysis is exactly like for the usual recorded inputs.

- if the pulses have been recorded and not the converted signal, a new resource module called Signal Operation is then available for this conversion.

- Do a post analysis on the signal:

- Click on connect track. Connect the "Ext synch" tracks to "signal op" by a "drag and drop". Press ok.

- Click again on connect track, a new track "signal op : Tors 1" now appear. It is the converted signal. You can use it in any plug in. press OK.

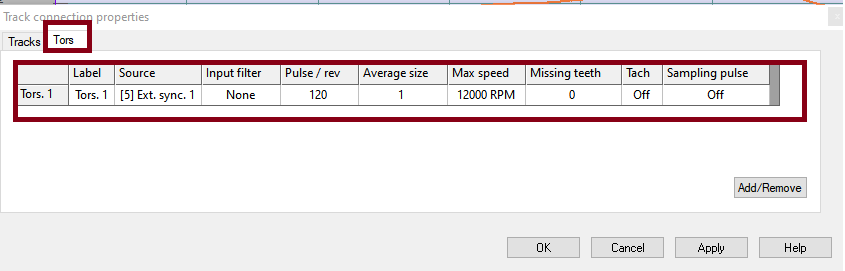

- The window below appears. On tab tors, you can define the torsional channel settings.

Twist measurements (static and dynamic)

The twist measurement consists in measuring the angle between the 2 side of a transmission shaft (or belt/chain). The measured angle is directly proportional to the stress and the applied torque. One common application is to choose an appropriate torsional damper.

The twist can be:

- Static: measure the transmitted torque and power. This is a not a dynamic result and is not to be analysed.

- Dynamic : measure the oscillating stress and resonances. This is a dynamic signal to be analyzed.

Both signals are calculated simultaneously by the virtual input module.

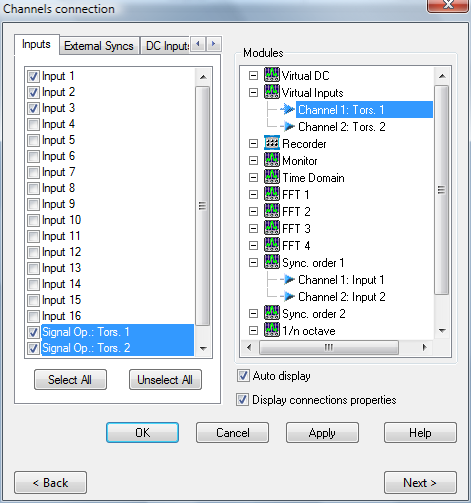

When the torsional signals are setup, simply connect it to the Virtual input plug-in.

To calculate the phase between the 2 sides of the twist it is necessary having a tachometer. This tachometer can come from any of the inputs or directly from one of the torsional signals using the Torsional + tach. mode. Having a missing tooth helps to have better accuracy.

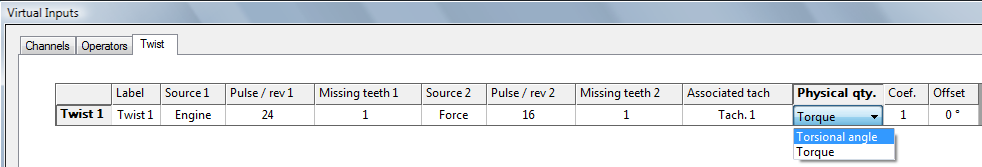

Then click on the Tools/Virtual inputs/dynamic button to open the virtual inputs setting. Click on the Twist tab. Select each torsional signal from the source 1 and source 2 lists.

The twist will be displayed in angle or torque. The coefficient is used to convert the read angle in torque.

The result are available from the add/Remove windows under the virtual input tab.

Note that any number of pulses/rev can be used for twist computation and these numbers of pulses/rev can either be different on each side.

The following table describes the differences between classical twist measurement and the OROS method:

| Classical twist measurement | OROS twist |

| Twist measurement force having the same number of pulse on each side. The difference between the 2 signals is requiring the same number of sample/rev. | Twist support different number of pulse/rev signals. The OROS twist algorithm is based on phase computation rather than pulse timing comparison. Thanks to this the analysis is independent from the number of pulses/rev. |

| Twist measurement based on integration of the angular speed (torsional) is not stable | Twist signal is stable and do not diverge. Indeed the OROS Twist algorithm does not use integration techniques |

Angular sampling for SOA analysis

The major improvement comes as a simple setting… with large effects. Indeed the possibility to sample the measured signal with a distributed angle pulses of a rotating shaft provides accurate results.

This applies mainly on machineries which feature cyclic variation of their rotating speed. Main ones are:

- Engines (Diesel, Gas, 2/4 strokes)

- Reciprocating pumps or compressors

- Transmission (Torque damper, belt, shaft)

- Electric machines (generator, alternator, motor)

The angular sampling allows getting the exact angle (or phase) of the events in the machine cycle. The results are event better using the time domain averaging (i.e. angular).

The following example shows the differences between a usual synchronous order analysis and the same one based on angular sampling. The phase differences are clearly visible especially on the ShaftView graphs.

With and without angular sampling Shaft view on an electric machinery bearing

Operations

In order to use the angular sampling function (Optional) it is necessary to have at least:

- A pulses train signal with a known number of pulses/rev

- phase reference (usually a 1 pulse/rev signal)

The sampling signal comes from an ext. synch input. The mode must be set to Sampling or any of the Sampling + xxx

It is necessary to associate a phase reference (the 0°) to the sampling pulse. It can be any tachometer or the sampling input itself. In this last case the 0° will be the first detected pulse or the missing pulse if there are some.

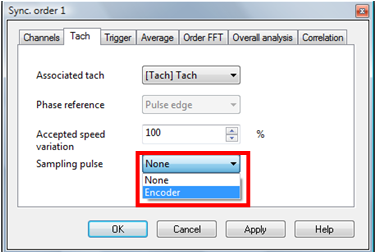

Then the Tachometer and the Sampling are assigned to a SOA plug-in.

The Sampling pulse setting defines if the angular sampling is activated or not:

- If set to None, the SOA will works on the regular way: Interpolation of the sampling dates from the RPM information).

- If set to a sampling input, the SOA will use it for sampling the channels signals

Advantages of the OROS solution

The angular sampling is an old technique, which used to be achieved by replacing the sampling clock by an encoder signal. Even if this procedure provides correct order and angles measurement, it has a lot of defects. The technique provided by oros corrects these defects.

The following table compares the possible signal alteration and the OROS solution

| Traditional angular sampling | OROS angular sampling |

| Results are not alias free. It is not possible to apply anti aliasing as the sampling frequency is not known by the acquisition system. | Alias free results. The results are not affected by the alias frequencies thanks to the re-sampling technique. Indeed the analyzer acquires the sample at high freq. (102.4 kS/s) and then re-samples it with a tracking anti-aliasing filter. |

| The number of pulses/rev. must be a power of 2. Because the digital Fourier transform need a power of 2 samples, if you need to analyze it in order domain (n Revolutions) it is compulsory to deliver n² samples per revolution. | Any number of pulse/rev and any angular resolution are possible. The re-sampling technique used by the SOA allows interpolating the correct number of pulse (n²) from any acquire number of pulses |

| Missing pulses are not supported. Obviously the missing pulses will conduct to missing samples. | Missing pulses are supported. The OROS torsional measurement is able to interpolate and create the missing pulses. Then the complete pulse sequence is used by the re-sampling algorithm. |

NVGate allows achieving angular sampled analysis avoiding the artefacts introduced by the direct angular sampling.