Difference between revisions of "NVGate Tachometer"

| Line 389: | Line 389: | ||

====Acquisition==== | ====Acquisition==== | ||

[[image:DC_tach acquisition.png|framed | [[image:DC_tach acquisition.png|framed|connected mode]] | ||

On acquisition mode, you need to activate a DC input on the frond tend, then activate the tach option | On acquisition mode, you need to activate a DC input on the frond tend, then activate the tach option | ||

Revision as of 10:28, 6 May 2020

NVGate can set up several tachometer sources, including virtual tachometers in the case of multiple shafts. Tachometers are based on signals that provide pulses/revolution or from a CAN bus or from a voltage proportional to the angular velocity.

Connect

Using GoToResult

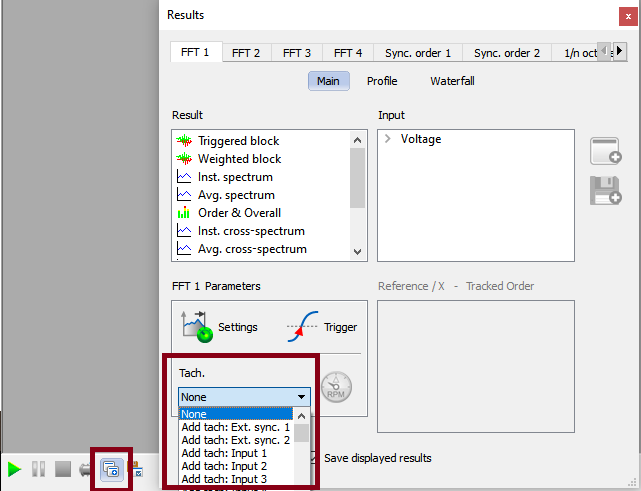

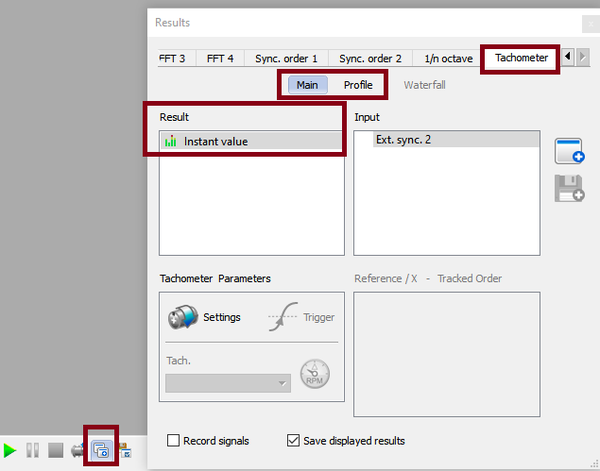

On this window, only input tachometer and ext. synch tachometer are available. To use it, just open the GoToResults windows, then select the tachometer.

Using Ribbon ASB

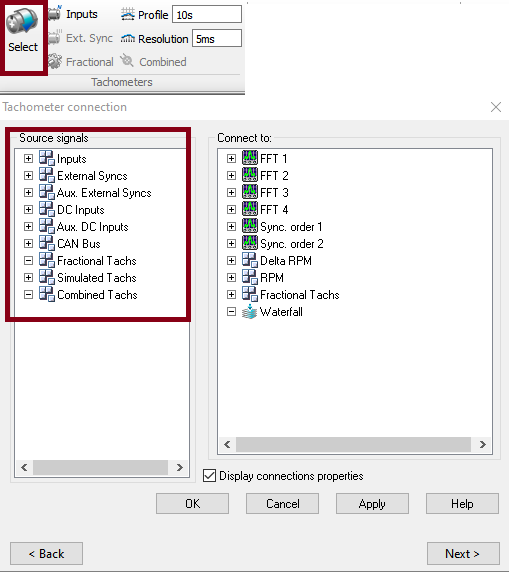

For more advanced option, on ribbon/acquisition tab, the left button (Select) allows dispatching the different tachometer type to the plug-in analyzers. The others items open the corresponding event detection setup.

Select: Shows the list of available tachometer sources and allows plugging it, to the plug-in, events and waterfall.

Available results and display

| Type | Size | Dimension | Domain | Save |

| Filtered signal | 256 pt | 2D | time | Display only |

| Angular speed | 1 pt | 1D | Angular speed | Display only |

| Ext Tach Angular speed | 1 pt | 1D | Angular speed | Display only |

| Virtual Angular speed | 1 pt | 1D | Angular speed | Display only |

| RPM Profile | 2048 pt max | 2D | time | Display only |

| Ext Tach Profile | 2048 pt max | 2D | time | Display only |

| Virtual Tach Profile | 2048 pt max | 2D | time | Display only |

All tach can be used as source for the RPM and Delta RPM event type and/or for order analysis (Constant band tracking of the FFT plug-in and Synchronous Order Analysis plug-in analyzers), and/or as a reference for the waterfall plug-in.

Display

| Using GoToResult | Using Add/remove windows |

|---|---|

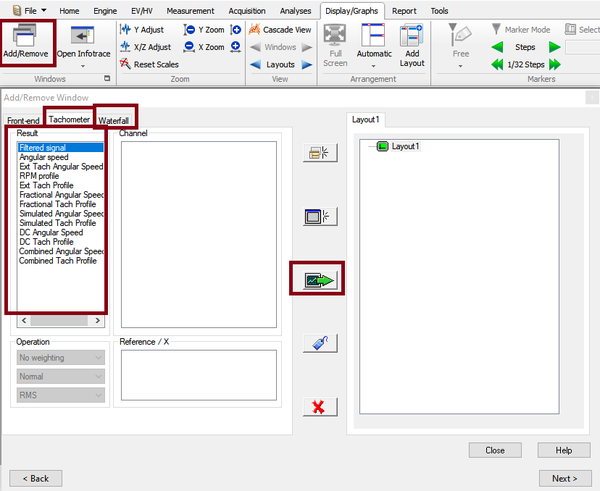

| You can display scalar value, or profile using GoToResult windows. First activate a tachometer in a window plug in. Second, A new tab is create : "tachometer". select the profile or scalar value | For advanced results not availabe in GoToResult Windows, use the: add/remove windows.

Tips : to create Advanced tachometer profile, put the scalar of tachometer into the waterfall |

Source overview

On NVGate we can set up several tachometer sources, including virtual tachometers in the case of multiple shafts. Tachometers are based on signals that provide pulses/revolution or from a CAN bus or from a voltage proportional to the angular velocity.

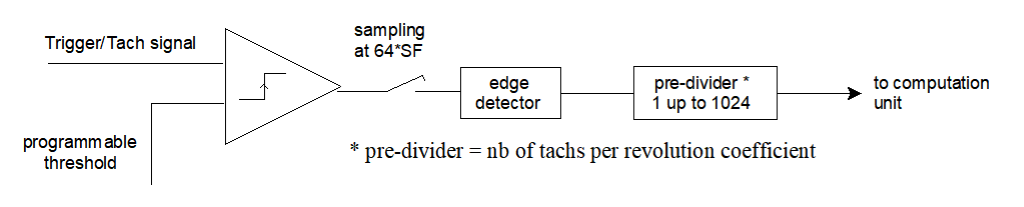

The tach probe that provides the pulse signal can be connected either on an input or on an External sync. The External sync is sampled at 64* the Front-end sampling frequency in order to achieve higher precision in delay or phase measurements.

Input: Tachs

![]() Inputs: Opens the properties dialog for the tachometers based on a dynamic input

Used to define up to 4 tachometers using signal from fast analog input (from the Front-end or from the Player).

Inputs: Opens the properties dialog for the tachometers based on a dynamic input

Used to define up to 4 tachometers using signal from fast analog input (from the Front-end or from the Player).

- Source:: the tach input signal (NONE by default). The input signal can be any Front-end input in Connected mode on line or any Player track in Post-analysis mode (except for the DC input and the Ext. Sync. inputs or tracks). (note : on OR35V1, Input 5 to input 8 are not able to be set as source using an OR35 analyzer.)

- Input filter: adds a digital filter before the tach process. The user can choose any filter from the list of the defined filters.

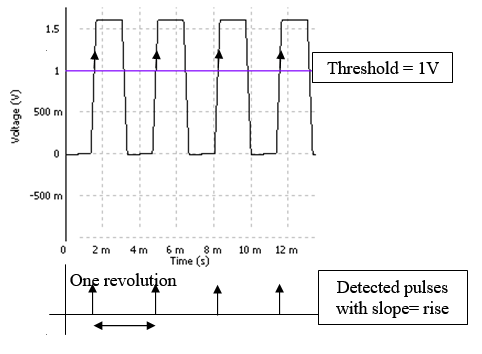

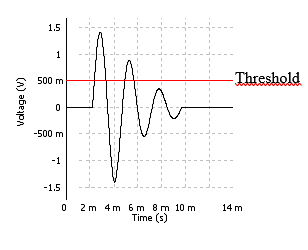

- Threshold: sets the signal threshold for tach pulse detection. The threshold is expressed in the same unit as for the input signal. The value can be adjusted between +/- the full scale of the input signal (depending of the input range).

- Slope: selects the input signal slope on which a tach pulse is detected.

| Slope | Description |

| Rise | Tach pulses are detected on rising edge of the input signal |

| Fall | Tach pulses are detected on falling edge of the input signal |

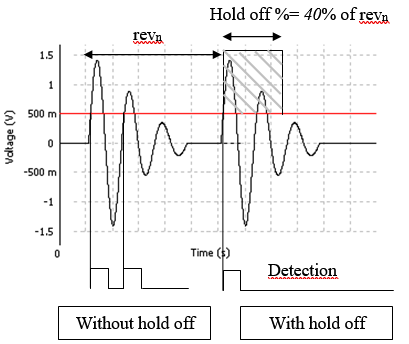

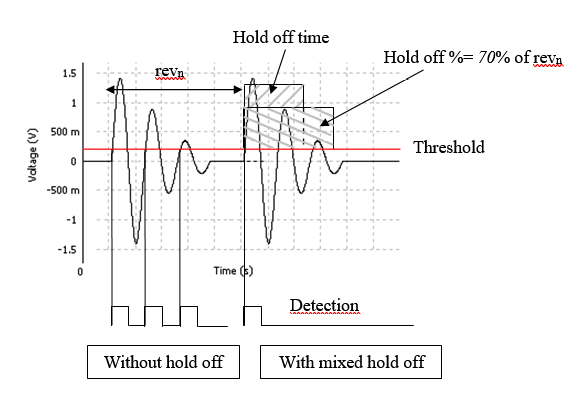

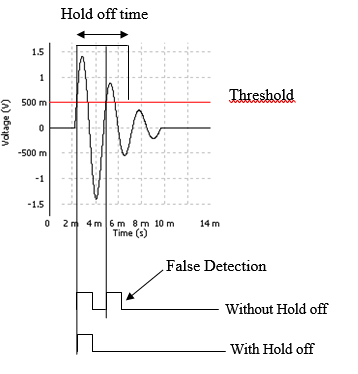

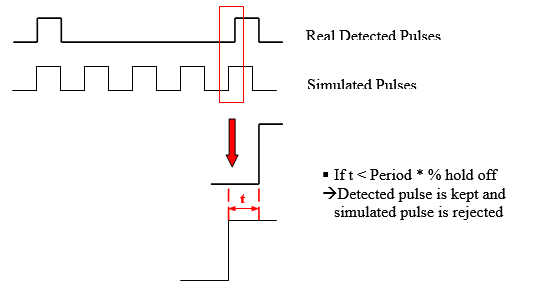

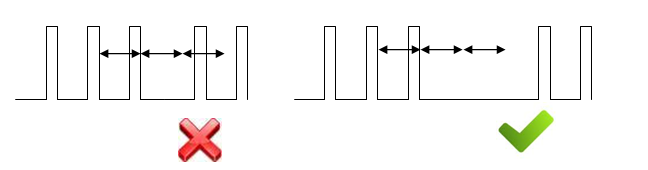

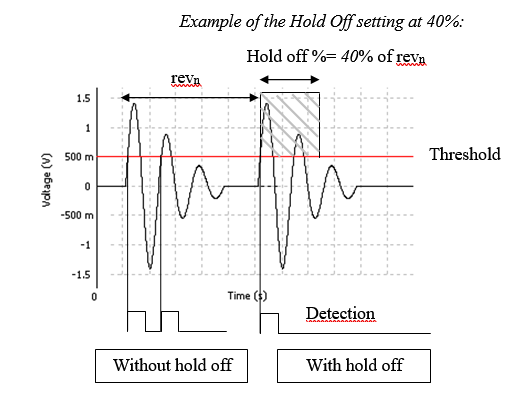

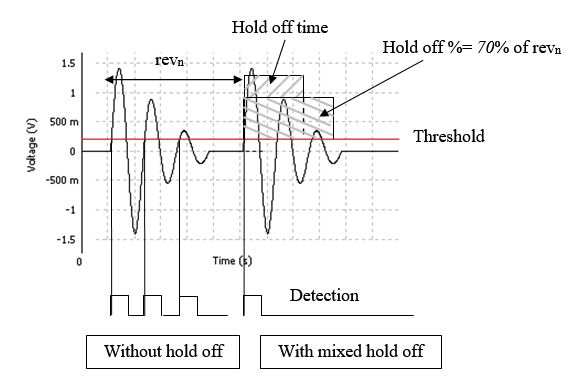

- Hold off: defines the minimum time (expressed in seconds) between two tach pulses used to measure angular speed. If a pulse is detected before this time has expired since the last valid pulse then the new pulse is rejected.

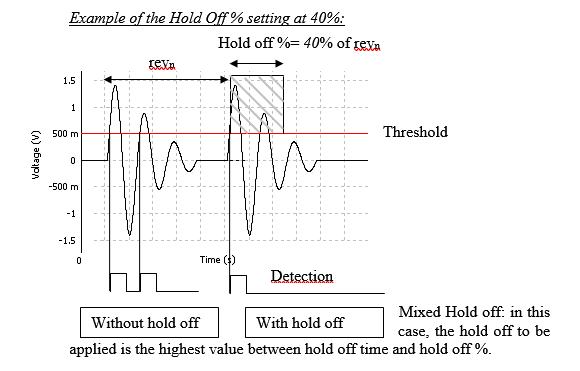

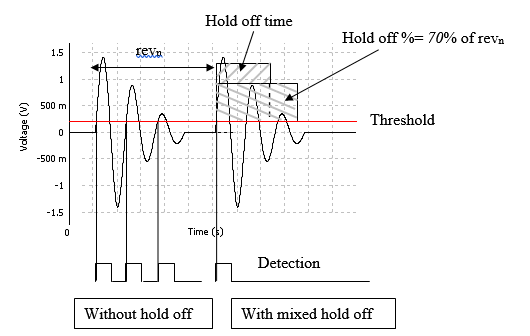

This minimum time is in fact the maximum between the Hold off setting value and the value computed using the last tach period length and the Hold off(% period) setting value. The user can enter any value between 0 and 36000s.

- Hold off (% period): defines the minimum time (expressed in % of the last valid tach period) between two tach pulses used to measure angular speed. If a pulse is detected before this time has expired since the last valid pulse then the new pulse is rejected.

This is used to reject angular speed variations that are too large. This minimum time is in fact the maximum between the Hold off setting value and the value computed using the last tach period length and the Hold off(% period) setting value.

- Mixed Hold off: in this case, the hold off to be applied is the highest value between hold off time and hold off %.

- Hystersis: defines the hystersis around the threshold. The value can be adjusted between 0 and the full scale of the input signal (depending on the input range). If Slope is set to RISE, the input signal must go below Threshold; Hystersis before a new pulse can be detected. If Slope is set to FALL, the input signal must go above Threshold + Hystersis before a new pulse can be detected. This setting is used to reject false pulse detection following, for example, an input signal transition.

- Pulse / rev: the number of pulses per revolution. The user can enter an integer value between 1 and 1024. For a non-integer number of pulses per revolution the user must use a virtual tach.

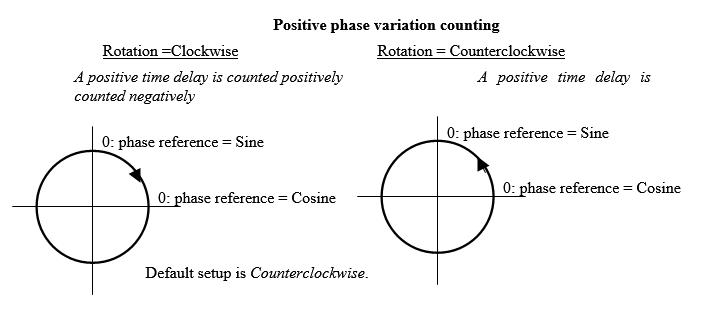

- Rotation: This setting defines the way the phase variation is counted: clockwise or counter-clockwise for each tachometer.

The rotation side is managed independently for each tachometer (Ext. sync, input, D, combined and fractional). Default setup is Counterclockwise;

See Ext Sync § for details

- Average size: defines the average number used to compute the average speed. Revolution number n average speed is: avrg_speed[n-1] + (inst_speed[n-1] - avrg_speed[n-1]) / avrg_size.

- Max speed: predefine a maximum angular speed to preset the scale and order tracking maxima. The limit of Max speed depends on the sampling frequency of the input signal and is equal to: 60 * Fe / (2 * 2.56) for the maximum. The Max speed setting is also used:

- to specify the limit of Y axis of the RPM profile result

- to compute the limit of the maximum order of the SOA plug-in analyzer.

- Min speed: defines the lowest measured angular speed. All revolutions with a speed lower than Min speed are forced to 0 RPM. By default Min speed is expressed in RPM. Min speed is automatically adjusted to Max speed/1000 but it is possible to go lower.

Ext. Tach

![]() : Ext. Synch:Opens the properties dialog for the tachometers based on a high speed oversampled Ext Synch input.Big text

In acquisition mode, the tach Ext synch come frome the frond end.

: Ext. Synch:Opens the properties dialog for the tachometers based on a high speed oversampled Ext Synch input.Big text

In acquisition mode, the tach Ext synch come frome the frond end.

In post analyse, we connect player track on tachometer Ext synch ressource.

Acquisition mode

Externals syncs are high speed levels comparator that provides accurate events date for the tachs and trigger. External sync is sampled at 64 time the Front-end sampling frequency in order to achieve higher precision in delay or phase measurements.

For external sync or tach signals whose frequencies overload the inputs sampling rate, an internal hardware divider is available in order to lower signal frequency. The upper frequency of the external sync must be lower than 64 times the Front-end frequency range. At input frequencies greater than 300 kHz, sensitivity can be decreased due to the electronic circuitry.

In any case the maximum frequency of a signal on an Ext Sync (before any pre-divider has been applied) is 375 kHz.

In acquisition mode, Ext synch channels are front end settings.

- Label: the name of this External Sync. (by default Ext. sync. n, with 1 <= n <= 2). The label of each External Sync is used in the result name and in all connection tools.

- Threshold: the detection level.

- Slope: the slope associated with the threshold that defines the trigger detection.

| Slope | Description |

| Rise | The threshold is reached on rising edge of the External sync. signal |

| Fall | The threshold is reached on falling edge of the External sync. signal |

- Hold off: defines the minimum time (expressed in seconds) between two pulses. If a pulse is detected before this time has expired since the last valid pulse then the new pulse is rejected. The user can enter any value between 0 and 36000s.

- Hystersis: defines the hystersis around the threshold. The value can be adjusted between 0 and the full scale of the input signal (depending on the input range).

- If Slope is set to RISE, the input signal must go below Threshold - Hystersis before a new pulse can be detected.

- If Slope is set to FALL, the input signal must go above Threshold + Hystersis before a new pulse can be detected. This setting is used to reject false pulse detection following, for example, a transition of the input signal. This setting can be displayed in dB.

- Pre-'divider': Hardware pre-divider is available after the edge detector and is used to reduce the frequency of the signal to be measured. When the tach is enabled, the measured speed take into account the pre-divider setting when displaying the true RPM value. The user can enter any integer value between 1 and 255. If tach is ’On’ this setting is linked to the ’pulse/rev’ setting.

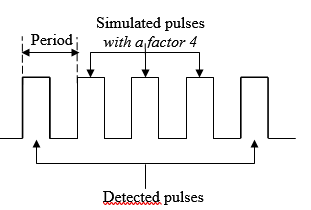

- Post'-mutiplier:' selection of the multiplier factor. It allows to generate an ’ExtSync’ signal which the pulse frequency is multiplied by the selected factor. The user can enter any integer value between 1 and 50. This is particularly used with slow time base as GPS or standard clock.

- Multiplier Hold off: defines the maximum time (expressed in percentage of the last period measured after multiplication) between a detected pulse and a simulated pulse. If a simulated pulse is detected before this time has expired since the detected pulse then this pulse is not added. By this way, the simulated signal is synchronize with the input signal. The user can enter any value between 1% and 99%.

- Physical qty.: the physical quantity applied to this External sync. It modifies the sensitivity and range peak units if necessary.

- Sensitivity: the sensitivity of the transducer. Changing it updates the range peak.

- Range pk.: the maximum input level for this channel, from 300mV up to 40V. For a sensibility of 2 V/m/s2 those values will be divided by 2 (0.015 m/s2 and 20 m/s2) and for a gain of 0.1 those values will be multiplied by 10 (3 V and 400V). This setting can be displayed in dB.

- External 'gain': this setting can be displayed in dB. This allows the analyzer to offset an external gain: for example if there is an external gain of 3dB, the value may be set to 3dB to retrieve the genuine amplitude of the signal.

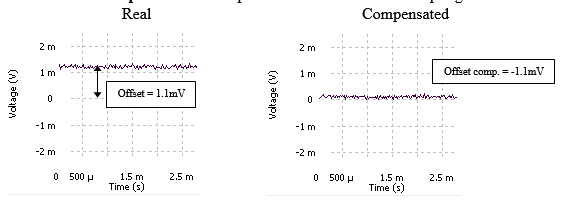

- Offset comp.: the offset compensation in Volts.

- Coupling: the coupling of this external sync.

This article compare the difference beetween coupling AC Vs DC for the tachometer phase.

| Coupling | Description |

| AC | AC coupling with signal ground connected to the analyzer hardware ground and a 0.35 Hz high pass filter. |

| DC | DC coupling with signal ground connected to the analyzer hardware ground. It is advisable to use the DC coupling when analyzing very low frequency (< 10 Hz frequency range). |

- Mode: This setting allows selecting available signal generated by the Ext. synch input to be used by the NVGate analysis components.

| Mode | Description |

| Trigger | The Input generates events only. It can be used as trigger, start and stop of plug-in analyzers and be recorded. Recorded event occurs as 0/1 V signals. Note that the trigger event remains available on any mode. |

| Tach | The input generates a tach signal (RPM and revolution phases) in addition to the events. See Tach § for details |

| Torsional | The input generates the instantaneous velocity measured with the F. to V converter<ref> Optional.</ref> from a pulses train. The torsional signal is considered as a dynamic input. It appears as Tors # in the inputs list (# being the Ext sync number) |

| Torsional + Tach | Same as above plus the tach signal is also available. The revolution phase correspond:

|

| Sampling | The detected pulses on the inputs will be used to synchronize the SOA re-sampling algorithm. The number of pulse/rev is f free and may be different from the SAO resolution. |

| Sampling + Tors | Combine the sampling and the Torsional modes. Both angular re-sampling and instantaneous velocity are provided by the input |

| Sampling + Tach | Combine the sampling and the Tachometer modes. Both angular re-sampling and RPM measurement are provided by the input |

| Sampling + tach + tors | Combine the sampling, the Tachometer and the Torsional modes. Angular re-sampling, Tachometer speed and instantaneous velocity are provided by the input |

- Hold off (% period): defines the minimum time (expressed in % of the last valid tach period) between 2 tach pulses used to measure RPM.

If a pulse is detected before this time has expired since the last valid pulse then the new pulse is rejected. This is used to reject angular speed variations that are too large. This minimum time is in fact the maximum between the Hold off setting value and the value computed using the last tach period length and the Hold off (% period) setting value.

Hidden/fixed: Hidden if Mode is Trigger or Torsional.

- Pulse / rev: the number of pulses per revolution. The user can enter an integer value between 1 and 4092. For a non-integer number of pulses per revolution the user must use a virtual tach.

Hidden/fixed: Hidden if Mode is Trigger.

- Rotation: This setting defines the way the phase variation is counted: clockwise or counter-clockwise for each tachometer.

The rotation side is managed independently for each tachometer (Ext. sync, input, D, combined and fractional).

- Average size: defines the average number used to compute the average speed. Revolution number n average speed is: avrg_speed[n-1] + (inst_speed[n-1] - avrg_speed[n-1]) / avrg_size.

Hidden/fixed: Hidden if Mode is Trigger.

- Max speed: defines the highest measured angular speed. All revolutions with a speed higher than Max speed are rejected. By default Max speed is expressed in RPM. The limit of Max speed depends on the sampling frequency of the input, on the pulse/rev and on the hold off. If the Max speed value is modified, the Min speed is automatically adjusted according to a speed ratio (MinSpeed = MaxSpeed / SpeedRatio). The Speed Ratio value is not able to be modified.

The Max speed setting is also used:

- to specify the limit of Y axis of the RPM profile result

- to compute the limit of the maximum order of the SOA plug-in analyzer.

Hidden/fixed: Hidden if Mode is Trigger.

- Min speed: defines the lowest measured angular speed. All revolutions with a speed lower than Min speed are forced to 0 RPM. By default Min speed is expressed in RPM. The user can enter any value between Max speed / 1000 and Max speed. The max Min speed and min Min speed are defined according to the Max speed and Speed ratio.

Hidden/fixed: Hidden if Mode is Trigger.

- Missing teeth: This setting indicates the number of possible consecutive missing teeth (no pulses). In such case depending on the active mode:

- Torsional: the system interpolates the missing pulses intervals in order to maintain the instantaneous speed at a continuous level during the missing pulses.

OROS torsional function is able to manage fractional pulses. It offers to achieve torsional measurement on the field in a simple and easy way.

The empty area (missing teeth) length at the piano tape junction must be included between 1 and 3 teeth. The number of missing teeth must be set to the exact number of missing teeth: In this example: 2.

Note: the total number of teeth includes the missing teeth.

Attention: The time lap of the first missing pulse must be longer than twice the time lap of the previous pulse interval

It is recommended to set the instrumentation in order to limit the number of missing pulse below 3s: Indeed long interval without pulses will lead to a strong order 1 artefact in the instantaneous speed signal due to interpolation of sample. Remaining below 3 missing pulse provide correct measurements

- Tach: the system uses the missing teeth occurrence as the phase reference.

Hidden/fixed: Hidden if Mode is Trigger

- Input filter: Select the filter to apply on the instantaneous angular velocity signal computed by the torsional converter. The applied bandwidth is the front-end one.

Hidden/fixed: Hidden if Mode is Trigger or Tach

In post Analyse

Used to define up to 6 Ext Tachs, using signal from the Ext. Sync. input from the Player). This replaces the Ext Sync (with tach ’On’) from the front-end, in Post-analysis. Then Ext tach is visible, on Track x connect the Ext Sync and then in the Ext tach set the source to Ext Sync.

- Label: the name of the tach.

- Source: the input signal of the tach (NONE by default). The input signal can be any Front end Ext. Sync. input (in Connected mode on line) or player track (in Post-analysis mode).

- Pulse / rev: the number of pulses per revolution. The user can enter an integer value between 1 and 1024. For a non-integer number of pulses per revolution the user must use a virtual tach.

Note: In Post-analysis, the number of pulses per revolution is added to the number entered for the acquisition.

- Rotation: This setting defines the way the phase variation is counted: clockwise or counter-clockwise for each tachometer.

The rotation side is managed independently for each tachometer (Ext. sync, input, D, combined and fractional). Default setup is Counterclockwise;

See Ext Sync § for details

- Average size: defines the average number used to compute the average speed. Revolution number n average speed is: avrg_speed[n-1] + (inst_speed[n-1] - avrg_speed[n-1]) / avrg_size.

- Threshold: sets the signal threshold for tach pulse detection. The threshold is expressed in the same unit as for the input signal. The value can be adjusted between +/- the full scale of the input signal (depending of the input range).

- Slope: selects the slope of the input signal on which a tach pulse is detected.

| Slope | Description |

| Rise | The tach pulses are detected on rising edge of the input signal |

| Fall | The tach pulses are detected on falling edge of the input signal |

- Hold off: defines the minimum time (expressed in seconds) between two tach pulses used to measure angular speed. If a pulse is detected before this time has expired since the last valid pulse then the new pulse is rejected. This minimum time is in fact the maximum between the Hold off setting value and the value computed using the last tach period length and the Hold off (% period) setting value. The user can enter any value between 0 and 36000s.

- Hold off (% period): defines the minimum time (expressed in % of the last valid tach period) between two tach pulses used to measure angular speed. If a pulse is detected before this time has expired since the last valid pulse then the new pulse is rejected. This is used to reject angular speed variations that are too large. This minimum time is in fact the maximum between the Hold off setting value and the value computed using the last tach period length and the Hold off (% period) setting value.

- Mixed Hold off: in this case, the hold off to be applied is the highest value between hold off time and hold off %.

Note: the hold off value in Post-Analysis is added to the time or the percentage already put for the acquisition.

- Max speed: predefine a maximum angular speed to preset the scale and order tracking maxima. The limit of Max speed depends on the sampling frequency of the input signal and is equal to: 60 * Fe / (2 * 2.56) for the maximum. The Max speed setting is also used:

- to specify the limit of Y axis of the RPM profile result

- to compute the limit of the maximum order of the SOA plug-in analyzer.

- Min speed: defines the lowest measured angular speed. All revolutions with a speed lower than Min speed are forced to 0 RPM. By default Min speed is expressed in RPM. Min speed is automatically adjusted to Max speed/1000 but it is possible to go lower.

- Missing teeth: This setting indicates the number of possible consecutive missing teeth (no pulses). In such case depending on the active mode:

- Torsional: the system interpolates the missing pulses intervals in order to maintain the instantaneous speed at a continuous level during the missing pulses.

- Tach: the system uses the missing teeth occurrence as the phase reference.

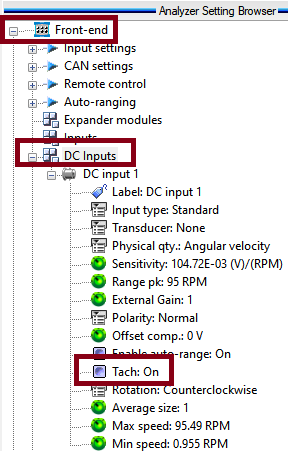

DC Tach

DC tach are voltage proportional to a speed. Be aware than phase measurement is not accurate with the method.

Acquisition

On acquisition mode, you need to activate a DC input on the frond tend, then activate the tach option

Tach: On / Off. Used to activate a tachometer with an RPM level proportional to the DC level Rotation: Depending on the way you look at a measured shaft or on the convention you are using, the shaft may be considered as rotating clock wise or counter clock wise. This has noticeable impact on the phase of spectra and orders.

Hidden/fixed: Hidden if Tach is Off.

Average size: defines the average number used to compute the average speed. Revolution number n average speed is: avrg_speed[n-1] + (inst_speed[n-1] - avrg_speed[n-1]) / avrg_size.

Max speed: defines the highest measured angular speed. speed higher than Max speed are rejected. By default Max speed is expressed in RPM.

The Max speed setting is also used:

- to specify the limit of Y axis of the RPM profile result

- to compute the limit of the maximum order of the SOA plug-in analyzer.

Post analyse

Up to 4 tachometers using signal from DC inputs can be activated. It’s particularly interesting if a tachometric transducer which delivers voltage proportional to rotational speed is used for the measurement (the sensitivity is in Volt/RPM). The actual speed is continuously known during the rotation.

When ’tach’ in DC input properties is activated several set-up become available:

- Max speed: predefine a maximum angular speed to preset the scale and order tracking maxima. The limit of Max speed depends on the sampling frequency of the input signal and is equal to: 60 * Fe / (2 * 2.56) for the maximum. The Max speed setting is also used:

- to specify the limit of Y axis of the RPM profile result

- to compute the limit of the maximum order of the SOA plug-in analyzer.

- Min speed: defines the lowest measured angular speed. All revolutions with a speed lower than Min speed are forced to 0 RPM. By default Min speed is expressed in RPM. Min speed is automatically adjusted to Max speed/1000 but it is possible to go lower.

- Rotation: This setting defines the way the phase variation is counted: clockwise or counter-clockwise for each tachometer.

The rotation side is managed independently for each tachometer (Ext. sync, input, D, combined and fractional). Default setup is Counterclockwise;

See Ext Sync § for details

- Average size: defines the average number used to compute the average speed.

- Notes:

- - The DC Input physical quantity must be angular velocity.

The connection of a DC Input is possible using the wizard toolbar and especially the tachometer connection window. If a DC Input is defined as a tach by this way, the set up ’tach’ is automatically activated and the physical quantity is forced to angular velocity.

- The sensitivity and the offset can be automatically updated by calibrating the DC Input.

Tachs DC in Post-Analyze.

In Post-Analyze, the DC tachs are available.

They can be activated and connected to a DC Input available in the signal loaded in the player. The set up magnitude, sensitivity and offset allow to calibrate the DC Input in post analyze to obtain the correct values of the angular velocity.

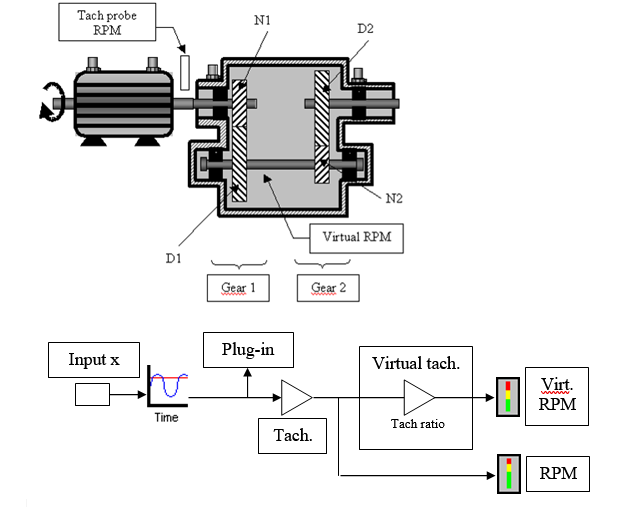

Fractional Tachs

![]() : Fractional: Opens the properties dialog for the tachometers that derives from another one. Fractional tach. computes RPM speed for a non accessible shaft by using gear ratio setting. Adapted for gear boxes and transmissions.

Note: the fractional tach. cannot be settled from the Vision interface, use the ASB for it.

Used to define up to 4 fractional tach, using data from the tach or the Ext Tach.

: Fractional: Opens the properties dialog for the tachometers that derives from another one. Fractional tach. computes RPM speed for a non accessible shaft by using gear ratio setting. Adapted for gear boxes and transmissions.

Note: the fractional tach. cannot be settled from the Vision interface, use the ASB for it.

Used to define up to 4 fractional tach, using data from the tach or the Ext Tach.

Virtual tach computes RPM speed for a not accessible shaft by using gear ratio setting.

- Label: the name of the output tach.

- Source: the source of a virtual tach can be any tach or Ext. tach.

- Tach ratio: this is the ratio between the output angular speed and the input angular speed. This setting is defined by the product of 2 fractions: N1/D1 * N2/D2 where N1, D1, N2 and D2 are integer values. Tach.1 / Tach.2 ratio maximum value cannot be higher than 2.

- Rotation: This setting defines the way the phase variation is counted: clockwise or counter-clockwise for each tachometer.

The rotation side is managed independently for each tachometer (Ext. sync, input, D, combined and fractional). Default setup is Counterclockwise;

See Ext Sync § for details

- Average size: defines the average number used to compute the average speed. Revolution number n average speed is: avrg_speed[n-1] + (inst_speed[n-1] - avrg_speed[n-1]) / avrg_size.

- Max speed: predefine a maximum angular speed to preset the scale and order tracking maxima. The limit of Max speed depends on the sampling frequency of the input signal and is equal to: 60 * Fe / (2 * 2.56) for the maximum. The Max speed setting is also used:

- to specify the limit of Y axis of the RPM profile result

- to compute the limit of the maximum order of the SOA plug-in analyzer.

- Min speed: defines the lowest measured angular speed. All revolutions with a speed lower than Min speed are forced to 0 RPM. By default Min speed is expressed in RPM. Min speed is automatically adjusted to Max speed/1000 but it is possible to go lower.

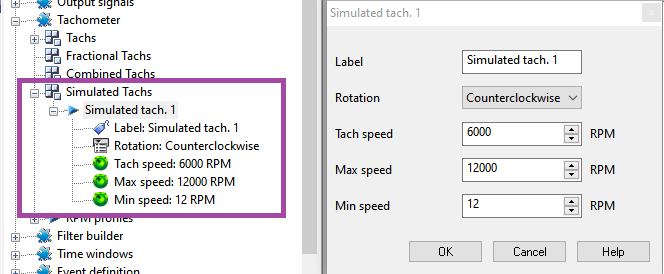

Simulated tachometer

This option is available for customers owning the FFTDiag option.

This feature will allow you to simulate a tachometer with a fixed speed for your measurement. This is useful when using a real tachometer sensor is not possible and your shaft is rotating at steady speed.

Setting up the simulated tach

You can use this tachometer as any tachometers to calculate order spectrums or save it as a result.

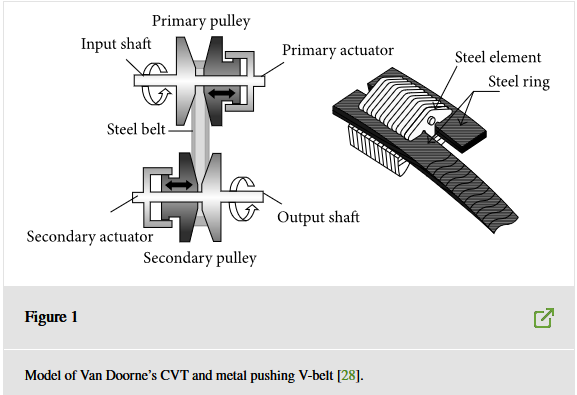

Combined Tach

![]() : Combined: Opens the properties dialog for the tachometers computed from other ones. Adapted for CVT. Note: the combined tach cannot be settled from the Vision interface, use the ASB for it.

: Combined: Opens the properties dialog for the tachometers computed from other ones. Adapted for CVT. Note: the combined tach cannot be settled from the Vision interface, use the ASB for it.

Application

The main application is in automtive : studying vibration due to a CVT gear box. We will first compute the speed of the belt with a continuously variable transmission (CVT)deducing by the speed of the 2 shafts. Then, with this belt speed, we can deduce vibration due to this belt using waterfall or order traking technics.

Exemple of study in CVT Vibration : https://www.hindawi.com/journals/sv/2015/857978/

How to use

This module allows computing tachometer information (Speed, Phase) relatively to 2 measured tachometers. Up to 4 different combined tach can be computed simultaneously. The combined tach can be used as any other standard tach.

- Label: the name of the output tach.

- Source 1 & 2: the calculation sources can be any tach or Ext. tach. Source 1 is called Rpm 1 and Source 2 is called Rpm2 in the formula.

- Rotation: This setting defines the way the phase variation is counted: clockwise or counter-clockwise for each tachometer.

The rotation side is managed independently for each tachometer (Ext. sync, input, D, combined and fractional). Default setup is Counterclockwise;

See Ext Sync § for details

- Average size: defines the average number used to compute the average speed. Revolution number n average speed is: avrg_speed[n-1] + (inst_speed[n-1] - avrg_speed[n-1]) / avrg_size.

- Max speed: predefine a maximum angular speed to preset the scale and order tracking maxima. The limit of Max speed depends on the sampling frequency of the input signal and is equal to: 60 * Fe / (2 * 2.56) for the maximum. The Max speed setting is also used:

- to specify the limit of Y axis of the RPM profile result

- to compute the limit of the maximum order of the SOA plug-in analyzer.

- Min speed: defines the lowest measured angular speed. All revolutions with a speed lower than Min speed are forced to 0 RPM. By default Min speed is expressed in RPM. Min speed is automatically adjusted to Max speed/1000 but it is possible to go lower.

- Formula: Allows editing the computation formula. The formula uses RPM1 as the speed of Source 1 and RPM2 as the speed of source 2. The computed tach speed is the result of the last line of the editor.

Copy/paste from or to a text editor are possible, to simplify the storage of different formula

Attention: All computation are done in SI unit (i.e: Rad/sec) the constant value must be expresses in Rad/sec.

Hereafter an example of computation of the belt speed in a car CVT:

R=97/2

K2=4*R*Pi/2

K3=2*R/Pi/120

Rt=Rpm1/Rpm2

Rtp1=Rt-1

Rtm1=Rt-1

R1=K2/Gp1

R2=1-K3*SQRT(Rtm1/Rtp1)

R1*R2*Rpm1

The formula editor accepts various math operators and functions such as square root, logarithms and power allowing polynomial equations. The following table gives the syntax of the operators and functions;

| In/out | Description |

| Chi | Channel i level |

| N.A. | The output level is the result of the last line in the editor |

| Operator | Description |

| + | Parameter or constant addition with another parameter or constant |

| - | Parameter or constant subtraction from another parameter or constant |

| * |

Parameter or constant multiplication by another parameter or constant |

| / | Parameter or constant division by another parameter or constant |

| ^ | Parameter or constant powered by another parameter or constant |

| = | Parameter affectation with the expression result at the right of sign |

| Function | Description |

| If(c, t, f) | Returns t if c is true or f if c is false (ex of c: I >4) |

| Rint(x) | Returns the nearest integer of x |

| Sign(x) | Returns -1 if x < 0, 0 if x = 0 or 1 if x > 0 |

| Function | Description |

| Sin(x) | Returns the sine of expression or parameter x |

| Cos(x) | Returns the cosine of expression or parameter x |

| Tan(x) | Returns the tangent of expression or parameter x |

| ASin(x) | Returns the arc sine of expression or parameter x |

| ACos(x) | Returns the arc cosine of expression or parameter x |

| ATan(x) | Returns the arc tangent of expression or parameter x |

| Sinh(x) | Returns the hyperbolic sine of expression or parameter x |

| Cosh(x) | Returns the hyperbolic cosine of expression or parameter x |

| Tanh(x) | Returns the hyperbolic tangent of expression or parameter x |

| ASinh(x) | Returns the hyperbolic arc sine of expression or parameter x |

| ACosh(x) | Returns the hyperbolic arc cosine of expression or parameter x |

| ATanh(x) | Returns the hyperbolic arc tangent of expression or parameter x |

| Log2(x) | Returns the base 2 logarithm of expression or parameter x |

| Log10(x) | Returns the base 10 logarithm of expression or parameter x |

| Log(x) | Returns the base 10 logarithm of expression or parameter x |

| Ln(x) | Returns the base e (natural) logarithm of expression or parameter x |

| Exp(x) | Returns the exponential of expression or parameter x |

| Sqrt(x) | Returns the square root of expression or parameter x |

| Abs(x) | Returns the absolute value of expression or parameter x |

| Min(x,y,…) | Returns the minimum level of listed parameters |

| Max(x,y,…) | Returns the minimum level of listed parameters |

| Sum(x,y,…) | Returns the sum of listed parameters |

| Avg(x,y,…) | Returns the average level of listed parameters |

| Predefined | Description |

| pi | Constant pi (3.1416…). Do not declare any constant with this name |

| e | Constant e (2.718). Do not declare any constant with this name |

Constants and parameters can be defined (except pi and e) using the = sign; eg: var1 = pi * 2 or var2 = rpm1/2. The constants may be defined once only.

Parameter/constant names must start with a letter and may be ended by a number.

The dot (.) is always the decimal separator independently from the OS preferences and the comma (,) is used as parameter separator.

The editor does not check the dimension of this result. The content of the formula can be copy/paste from any text editor.

RPM Profiles

Defines the RPM profile window display.

: Profile: Set up the tachometer profiles duration. These graphs are available for the Tachometer module in the Add/Remove graph dialog.(from 10s to 1200s).

: Profile: Set up the tachometer profiles duration. These graphs are available for the Tachometer module in the Add/Remove graph dialog.(from 10s to 1200s).

The profile displays continuously the tachometer speeds with a memory depth defined by the profile setting.

- Hidden/fixed: fixed to a value equal to Duration profile / 2048.