Difference between revisions of "NVGate 2023: Release note"

| Line 109: | Line 109: | ||

The add-on reads from Modbus server the entries which are synchronized with '''dynamic / parametric / Ext. sync. | The add-on reads from Modbus server the entries which are synchronized with '''dynamic / parametric / Ext. sync.''' channels acquired from OR3X analyzer, and reinjects the entries to NVGate in real-time using simulated DC channels. These values are then managed as DC data in NVGate. The entries can be saved as '''properties''' of projects / measurements automatically. They can also be used to '''trigger''' measurements (recorder, SOA, waterfall …). | ||

Revision as of 11:11, 27 November 2023

OROS strives to be closer to its users, carefully listening to needs and requests. For that reason, OROS regularly releases new versions. Customers under contract automatically benefit from each release.

The NVGate® 2023 (V16), which is compatible with our latest hardware O4 and new solution Monitoring, became available in February 2023.

The NVGate® 2023.1 major version became available in November 2023. This release of the OROS 3-Series analyzer’s software platform brings additional functionalities and significant performance improvements. Below is a summary of the main enhancements of your NVGate experience:

>> 3 main features to avoid dramatic mistakes and bring efficiency to maximum

This release note describes the content of the version, with operating details.

To download and install NVGate 2023.1, check this page.

Compatibility: NVGate 2023 is compatible with all OROS instruments (O4 - OR34 - OR10 - OR35 V1/TW - OR36 V2/TW - OR38 V2/TW) that have not been discontinued. Depending on the hardware options and version, some instrument features may or may not be available.

NVGate ADVISOR: Expert by your side all the time !

NVGate ADVISOR: Expert by your side all the time !

Have you ever hesitated in selecting analysis parameters ?

Have you ever spent hours trying to figure out why results are not as expected ?

Have you ever ended up with useless measurement data due to slight negligence in settings ?

As a beginner, have you ever wished to have an expert to check your settings, fix mistakes and explain why ?

As an expert, have you ever wished to be notified when you made the rookie mistake?

With NVGate ADVISOR, the metrology watchdog developed with OROS know-how accumulated over 40 years, you will always be accompanied by a noise and vibration expert.

NVGate ADVISOR brings to the user:

Notification

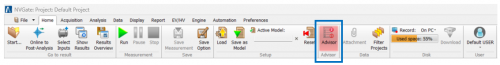

When one or more issues are detected, the user will be notified immediately by the “Advisor” icon in the “Home” tab and “Analysis” tab,

or by the icon at the lower right corner of NVGate.

The number shown in the icon is the number of new (unread) Advices generated after the last time the user checked the Advisor window.

There are three levels of notification, which are color coded:

![]() Error (red): It is certain that a mistake occurs, and the measurement will not be done correctly.

Error (red): It is certain that a mistake occurs, and the measurement will not be done correctly.

![]() Warning (yellow): It is well likely that a mistake occurs based on our know-how.

Warning (yellow): It is well likely that a mistake occurs based on our know-how.

![]() Suggestion (blue): It might not be a mistake, but probably a negligence.

Suggestion (blue): It might not be a mistake, but probably a negligence.

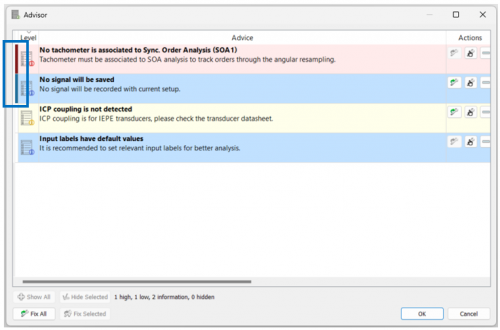

Explanation and suggestion

Click on the Advisor icon, and the Advisor window will be opened. The bar in the beginning means that this Advice is new and unread. In each Advice, the explanation of the detected issue is given, and corresponding solution or suggestion is proposed to assist the user to set up properly and obtain correct measurements. Based on the information, the user can decide to fix the issue or ignore it.

Actions

![]() Auto-fix: When this icon is activated, the solution proposed in the Advice can be applied automatically. With auto-fix, it becomes easy to set up NVGate properly in minimal time. NVGate configuration remains available for your own settings.

Auto-fix: When this icon is activated, the solution proposed in the Advice can be applied automatically. With auto-fix, it becomes easy to set up NVGate properly in minimal time. NVGate configuration remains available for your own settings.

![]() Manual-fix: Clicking this icon will open the configuration window containing the parameter which is suggested to be modified. User can solve the issue manually by following the suggestion given in the Advice.

Manual-fix: Clicking this icon will open the configuration window containing the parameter which is suggested to be modified. User can solve the issue manually by following the suggestion given in the Advice.

![]() Ignore: User can hide the Advice which is not concerned.

Ignore: User can hide the Advice which is not concerned.

![]() Fix-all: For all the Advices in the list that can be fixed automatically, the solutions will be applied.

Fix-all: For all the Advices in the list that can be fixed automatically, the solutions will be applied.

![]() Show-all: All the ignored Advices will be shown again.

Show-all: All the ignored Advices will be shown again.

Advisor works in both online and post analysis modes, helping user to properly set up NVGate efficiently. The majority of current Advices are for the application of impact testing and rotating machine analysis, and more Advices covering a wider range of applications will be available in the future NVGate versions.

Modbus TCP/IP client add-on compatibility

Modbus TCP/IP client add-on compatibility

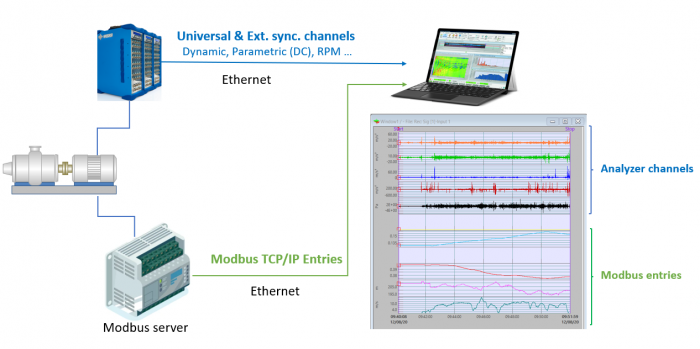

The new Modbus TCP/IP client add-on is available now. It reads entries from Modbus server and injects the data to NVGate in real-time.

The add-on reads from Modbus server the entries which are synchronized with dynamic / parametric / Ext. sync. channels acquired from OR3X analyzer, and reinjects the entries to NVGate in real-time using simulated DC channels. These values are then managed as DC data in NVGate. The entries can be saved as properties of projects / measurements automatically. They can also be used to trigger measurements (recorder, SOA, waterfall …).

Requirements: the PC running the Modbus TCP/IP client add-on should host at least 2 Ethernet connectors. One is dedicated for OR3X analyzer, and the other is for establishing connection to the Modbus server. The Modbus server is identified with an IP address and a port number.

Tachometer setup becomes hassle-free

Tachometer setup becomes hassle-free

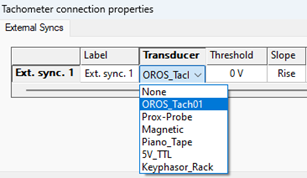

When pulses from tachometers are acquired by Ext. Sync. inputs, user needs to know the delivered outputs in order to correctly set up parameters, for example, threshold, coupling, range peak and so on. In addition, properly setting up max speed, which is linked to the shaft speed, is crucial for a successful analysis such as order tracking. However, sometimes it could be difficult for the users to understand all these settings.

The most common rotating speed sensors are now available in the transducer database. User simply selects the sensor from the transducer list, and the tachometer settings are ready.

The transducers in the list can be customized, and new transducers can be added by editing the file “Tachometers.tdb”, which can be found in the installation directory of NVGate.

Enhanced ERGONOMICS : Save more clicks and push teams efficiency to the limits

Enhanced ERGONOMICS : Save more clicks and push teams efficiency to the limits

Experience the enhanced field ergonomics and intuivity thanks to the optimized new Ribbon Tabs and application-oriented default settings. NVGate 2022 bring settings and displays at your fingertips in less clicks.

The interface gathers the analyzers functionalities in simple, clear and easy to identify tabs organized according to the main operations (Home, Acquisition, Analysis, Data, Display, Report, Automation, Preferences).

New default settings

The default settings in NVGate have been updated to the ones below. With these default settings, you can do rotating analysis measurement directly. Be aware that if you load an exiting project, the settings will not be affected. You can also easily change these settings.

FFT Overlap: 66%

FFT lines: 3200

FFT Overall low freq : 2 Hz

SOA resolution: 1/8

SOA overlap: 5

SOA OVL lower order: 0.2

Event Delta RPM: Delta velocity 10 rpm

Waterfall Depth: 1000

Tachometer/RPM Profiles/Duration: 120 sec

New Sound Power V3.20

OROS SOUND POWER Solution has been designed to let you achieve that type of test in the most efficient and accurate way.

This new version includes the following improvements:

- New command to start directly the software on your pre-configured setup

- Option to modify the limit of overall octave filter

- Excel templates fully updated to the last standard

- Full compatibility with NVGate 2022.

Read the dedicated Sound Power 3.20 release note for more info.

Bug fixing

- 14729: CANBus J1939 compatibility

- 15258: CANBus: Add CAN 2.0B

- 15376: Tortional velocity measured from tacho at slow speed becomes 0

- 15372: Phase difference between online results and post-analysis results

- 15329: Integrator filter on accelerometer in teamwork mode, value in post-analysis is not velocity

- 15314: In Japanese OS, “Next” button is not correctly loaded in display window

- 15301: In cascade mode, the calibration process takes too long

- 15299: No explicit error message when trying to load a post-analysis workbook in cascade mode

- 15297: Rename measurement in teamwork mode, need to press refresh to see the change

- 15293: Display reference profile waterfall is limited to 20 channels

- 15220: The orbits (lissajou) in post-analysis are (sometimes) different from Online measurements

- 15167: Signal corrupts with double sampling frequency in V16

- 15147: Time marker mix-ups with several signals in the same project

- 15124: Increase the number of spare units

- 15047: Converting OR10 signal to ORXF format doesn’t work with CAN channels

- 14913: 2 "Channel connection properties" windows at once

- 14025: Press cancel when asked to save the measurement, the sequence jumps ahead