Difference between revisions of "Modal Data Acquisition"

(Created page with " ==Data acquisition== Data acquisition is a critical step for modal analysis: without correct data, no exploitable results. Thanks to the direct acquisition implemented in Mo...") |

|||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[category:Modal]] | |||

==Data acquisition== | ==Data acquisition== | ||

| Line 80: | Line 80: | ||

[[Image:Modal_Manual_110.png|framed|none]] | [[Image:Modal_Manual_110.png|framed|none]] | ||

'''Health:''' if overload or double hit happens, then Health LED becomes red. | |||

When the acquisition is completed, press the button of [[Image:Modal_Manual_111.png]] or [[Image:Modal_Manual_112.png]] to transfer the data to the Modal main interface and start the modal identification. | When the acquisition is completed, press the button of [[Image:Modal_Manual_111.png]] or [[Image:Modal_Manual_112.png]] to transfer the data to the Modal main interface and start the modal identification. | ||

Latest revision as of 09:48, 5 July 2021

Data acquisition

Data acquisition is a critical step for modal analysis: without correct data, no exploitable results. Thanks to the direct acquisition implemented in Modal, enjoy the Teamwork analyzers power and accuracy with a dedicated interface for structural acquisition. The interface works with the different excitation modes: impact hammer, shaker, operating excitation.

To excite a large structure, up to 6 shakers per analyzers can receive signals from generators outputs. In order to fit the wide range of potential cases, the complete series of excitation signals from random, chirp, swept sine, stepped sine to normal modes can be generated.

For high channel count applications, Teamwork technology cascades several analyzers together to acquire simultaneously hundreds of channels. Teamwork instruments guarantee an efficient instrumentation thanks to the different possible configuration.

For example, this flexibility allows to highly reduce the cable length by distributing the instruments along the structure under test.

The direct data acquisition (DAQ) module is available in Modal, which enables you to complete a modal test easily and quickly.

Launch the DAQ by clicking the "Data Acquisition" item, shown as the following.

Then the geometry modeled in Modal will be transferred to DAQ automatically.

To perform a complete modal acquisition, follow the different steps described here.

Test planning

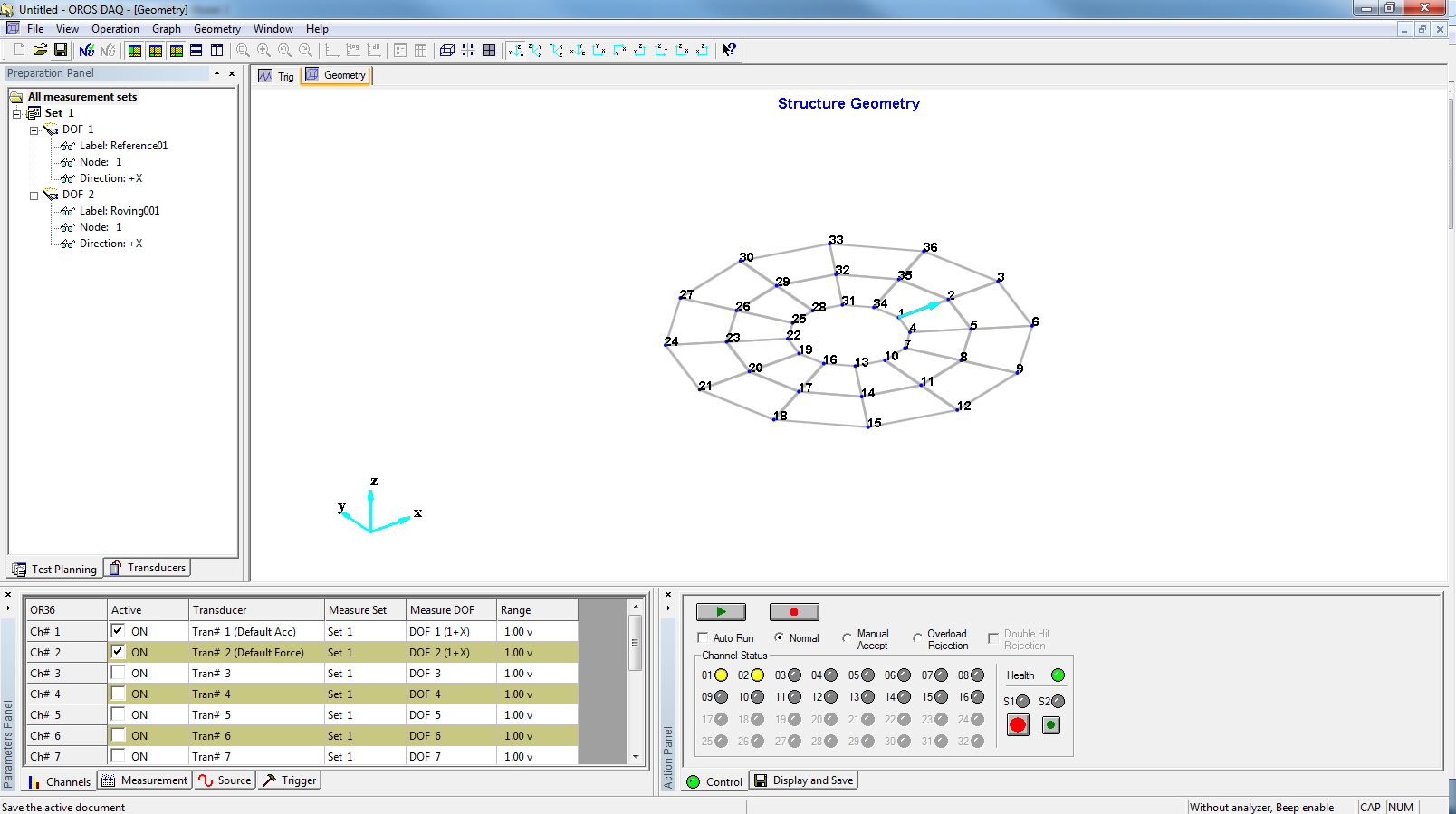

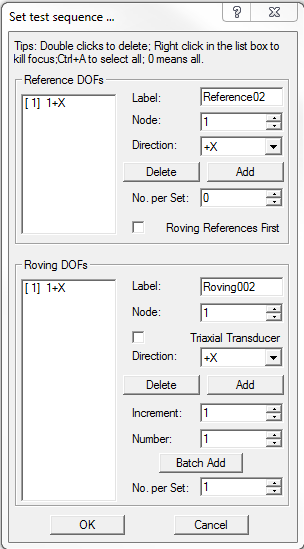

In the preparation panel, set the test planning.

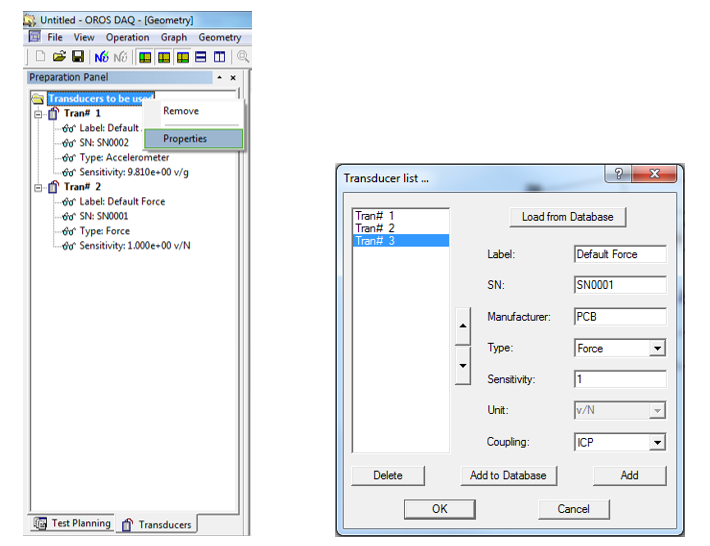

Transducers definition

Set the transducer list in the ’Transducers’ page of Preparation Pane. Note to select the correct transducer type and fill the correct sensitivity.

Check the different mesurements directly on the geometry

The references are displayed in red and the roving DOFs in green.

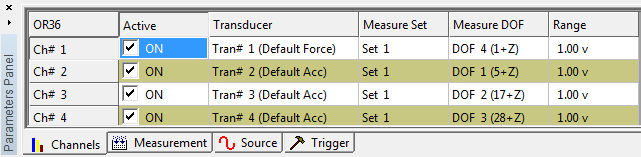

Measurement parameters setup

- Parameters Panel->Channel: set range for each active channel; match them to the corresponding measurement DOFs and transducers.

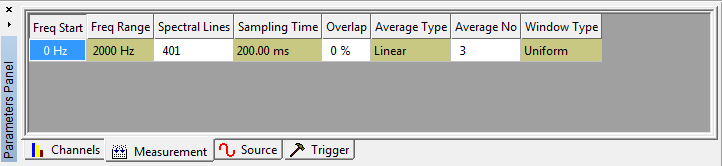

- Parameters Panel->Measurement: set the frequency range, spectral lines, average number, and window type.

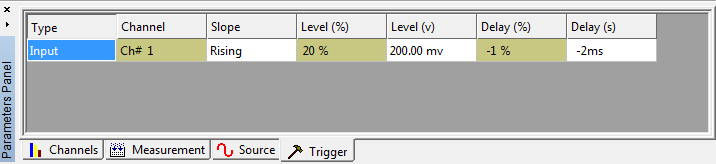

- Parameters Panel->Trigger

Display ans save options

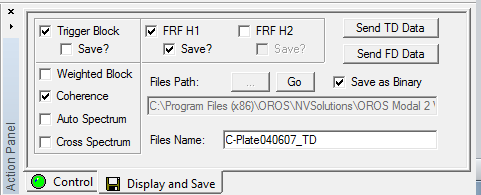

Action Panel->Display and Save: set the data blocks you want to display and export. As the following graph, trigger block, FRF H1, and coherence will be displayed, trigger block and FRF H1 will be exported in the Binary UFF format. You can go to this data storage directory to check files by pressing button ![]() .

.

Analyzer connection

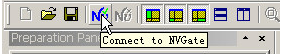

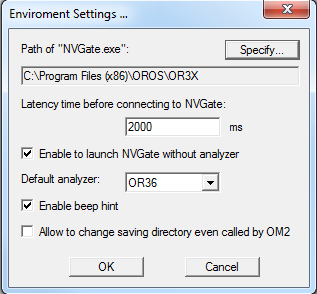

Click the button on the toolbar showed as the following to lunch NVGate and connect to it. During this process, you may be asked to operate the wizard of NVGate. You should confirm that the NVGate has been launched successfully before pressing the ’OK’ button.

If necessary, you may need to set the environment parameters of DAQ by the menu of ’Operation’->’Environment setting’. Please refer to the online help of DAQ for more details

Note that for acquisition with several synchronized analyzers, NVGate V10 minimum is required.

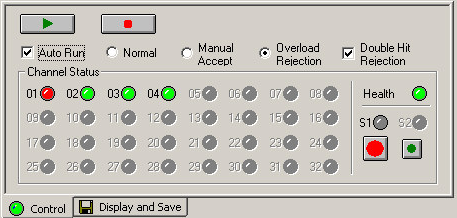

Acquisition control

Control Panel->Control: press ![]() to begin the measurement,

to begin the measurement, ![]() to pause, and

to pause, and

![]() to stop. If the ’Auto Run’ option is checked, the measurement sets will be executed automatically one by one, you don’t need to press the button

to stop. If the ’Auto Run’ option is checked, the measurement sets will be executed automatically one by one, you don’t need to press the button ![]() after one measurement set is finished. ’Normal’, ’Manual Accept’ and ’Overload Rejection’ are different modes to accept the triggered data. You can also set ’Double Hit Rejection’ to reject the continuous hits when performing a hammer impact test to get better measurement quality.

after one measurement set is finished. ’Normal’, ’Manual Accept’ and ’Overload Rejection’ are different modes to accept the triggered data. You can also set ’Double Hit Rejection’ to reject the continuous hits when performing a hammer impact test to get better measurement quality.

Health: if overload or double hit happens, then Health LED becomes red.

When the acquisition is completed, press the button of ![]() or

or ![]() to transfer the data to the Modal main interface and start the modal identification.

to transfer the data to the Modal main interface and start the modal identification.